1.测试条件

产品测试条件:温度:5~35℃, 湿度:45%~85%R.H., 气压:860 ~1060hPa。

标准测试条件:温度:25±3℃, 湿度:60±10%R.H. 气压:860 ~1060hPa

| 1 | 额定电压(Vo-p) | 3.0Vo-p |

| 2 | 工作电压(Vo-p) | 2.5~4.5 Vo-p |

| 3 | 额定电流(mA) | Max.100mA ,at 4000Hz 50% duty Square Wave 3.0Vo-p |

| 4 | 输出音压(dB)10cm | Min. 75dB,at 4000Hz 50% duty Square Wave 3.0Vo-p |

| 5 | 电阻(Ω) | 12±3Ω |

| 6 | 谐振频率(Hz) | 4000Hz |

| 7 | 工作温度(℃) | -20℃~+70℃ |

| 8 | 储存温度(℃) | -40℃~+85℃ |

| 9 | 净重(g) | Approx 0.1g |

| 10 | 环保 | Yes |

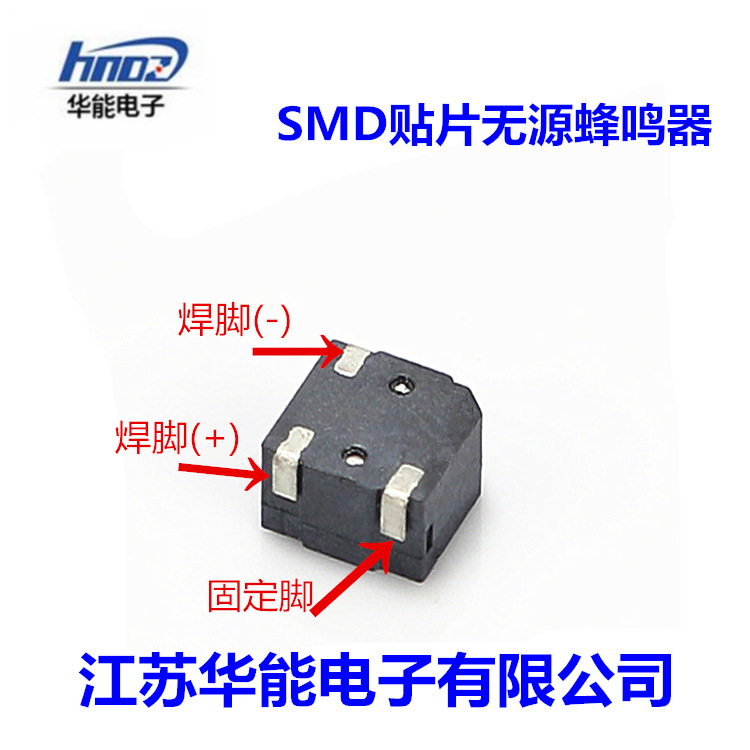

2.尺寸图 单位: mm

基本公差: 除特殊注明外,一般公差为±0.3mm

外壳材料: Black LCP

3.电性能及声音测试条件

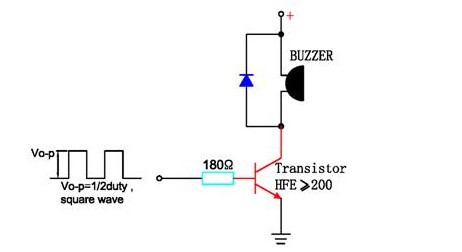

测试电路 测试装置

谐振频率是占空比为50% 的方波,信号电压要足够让晶体管饱和工作。

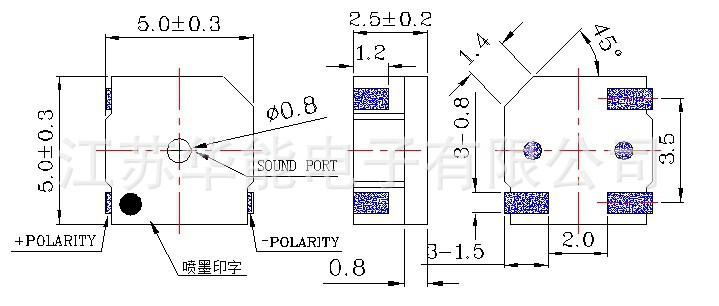

4.频响曲线

在3Vo-p占空比为50%的方波,测试距离为10cm的条件。

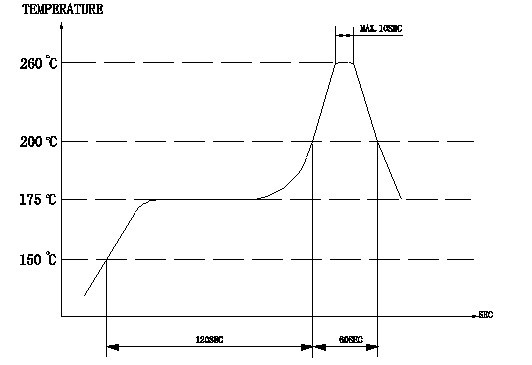

5.回流焊条件

5.1 回流焊曲线图

注意事项: (1) 产品经过回流焊机后,所有电性能要保持在规格书的范围内。

(2)回流焊的操作温度一定要在推荐范围之内。如果超出范围都有可能影响到产品的性能。

5.2 焊盘位置

6.可靠性测试

在下面任何一项测试后都要符合以下标准,外观和电性能(除声压外)上不能有不良或衰减现象出现,声压不能低于规格说明书的最低声压的10dB。

6.1 寿命测试

将测试件置于25±10℃的温度下,输入额定电压、占空比为1/2的谐振频率方波测试96小时。

6.2 高温测试

将测试件置于-30℃的温度下存放96小时,取出置于常温下3小时而后测试。

6.3 低温测试

将测试件置于-30℃的温度下存放96小时,取出置于常温下3小时而后测试。

6.4 湿度测试

将测试件置于温度+40±3℃,湿度90%~95%的条件下持续48小时,再置于室温下3小时而后测试。

6.5 温度冲击测试

将测试件置于以下温变条件下:60℃1小时→25℃3小时→-20℃1小时→25℃3小时(1周期),做完一个周期实验,过1个小时后再继续下一次实验,总测试周期数: 10个周期。

6.6 落地测试

将测试件标准包装后(包装盒的3个边6个面)从75厘米的高度下跌落到厚木板或5厘米厚的硬木板上。

6.7 机械振动测试

按以下条件实验后再测试:振速:1000次/分;振幅:1.5毫米;时间: 1小时更换一个自由度方向共3个自由度方向。

注意:

需避免无关材料进入产品内,无关材料如:磁性材料、水溶性的材料、腐蚀性的气体等。因为这些无关材料将会影响产品的电性能。

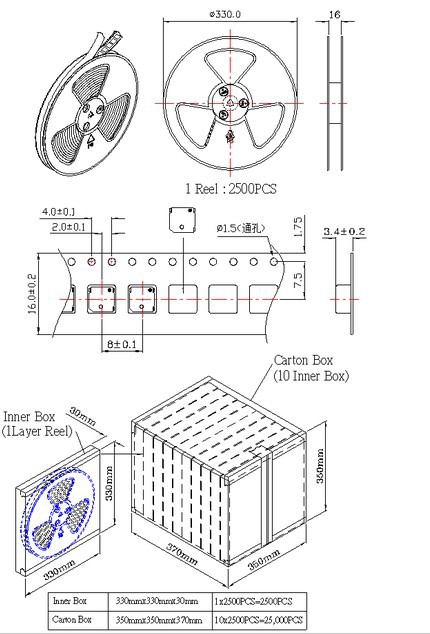

7.包装

SPECIFICATION

| No. | Item | Unit | Specification | Condition |

1 | Oscillation Frequency | Hz | 4000 | Vo-p=1/2duty , square wave |

2 | Operating Voltage | Vo-p | 2 ~ 4 |

|

3 | Rated Voltage | Vo-p | 3 |

|

4 | Current Consumption | mA | MAX. 110 | at Rated Voltage |

5 | Sound Pressure Level | dB | MIN. 75 | at 10cm at Rated Voltage |

6 | Coil Resistance | Ω | 12±3 |

|

7 | Operating Temperature | ℃ | -30 ~ +70 |

|

8 | Storage Temperature | ℃ | -40 ~ +85 |

|

9 | Dimension | mm | 5.0 x 5.0 x H2.5 | See appearance drawing |

10 | Weight (MAX) | gram | 0.1 |

|

11 | Housing Material |

| LCP( Black ) |

|

12 | Leading Pin |

| Tin Plated Brass(Sn) | See appearance drawing |

13 | Environmental |

| RoHS |

|

C. APPEARANCE DRAWING

Tol : ± 0.3 Unit: mm

D.TESTING METHOD

Standard Measurement conditions

Temperature:25±2℃ Humidity:45-65%

Acoustic Characteristics:

The oscillation frequency, current consumption and sound pressure are measured by the

measuring instruments shown below

In the measuring test, buzzer is placed as follows:

E. Typical Frequency Response Curve

F. Recommend Driving Circuit

The base current Ib should high enough so that it saturates the collector current of the transistor with the CB load.

G. Soldering Condition

(1)Recommendable reflow soldering condition is as follows

(Reflow soldering is twice)

Note:It is requested that reflow soldering should be executed after heat of product goes down to normal.

Heat resistant line

(Used when heat resistant reliability test is performed)

(2)Manual soldering

Manual soldering temperature 350 ℃ within 5 sec.

H. RELIABILITY TEST

NO. | ITEM | TEST CONDITION AND REQUIREMENT |

1 | High Temperature | After being placed in a chamber with 85 |

2 | Low Temperature | After being Placed in a chamber with -40 |

3 | Humidity Test | After being Placed in a chamber with 90-95% R.H. at 40 |

4 | Temperature Cycle | The part shall be subjected to 5 cycles. One cycle shall be consist of: |

5 | Drop Test | Drop on a hard wood board of 4cm thick, any directions ,6 times, at the height of 75cm . |

6 | Vibration Test | After being applied vibration of amplitude of 1.5mm with 10 to 55 Hz band of vibration frequency to each of 3 perpendicular directions for 2 hours . |

7 | Solderability | Lead terminals are immersed in rosin for 5 seconds and then immersed in solder bath of +300 |

8 | Terminal Strength | The force of 9.8N(1.0kg) is applied to each terminal in axial direction for 10 seconds. |

TEST CONDITION.

Standard Test Condition : a) Temperature : +5 ~ +35℃ b) Humidity : 45-85% c) Pressure : 860-1060mbar

Judgment Test Condition : a) Temperature : +25 ± 2℃ b) Humidity : 60-70% c) Pressure : 860-1060mbar

I. PACKING STANDARD