江苏华能电子有限公司 | ||||||||||||||||||||||||||||

承 认 书 Specifications

客户承认签署

公司地址: 江苏省兴化市陈堡镇工业集中区 Em.: jshndz208@163.com Tel: +86-523-83724803 Fax: +86-523-83724866 | ||||||||||||||||||||||||||||

江苏华能电子有限公司 | |||||

性能参数 Electrical Characteristics | |||||

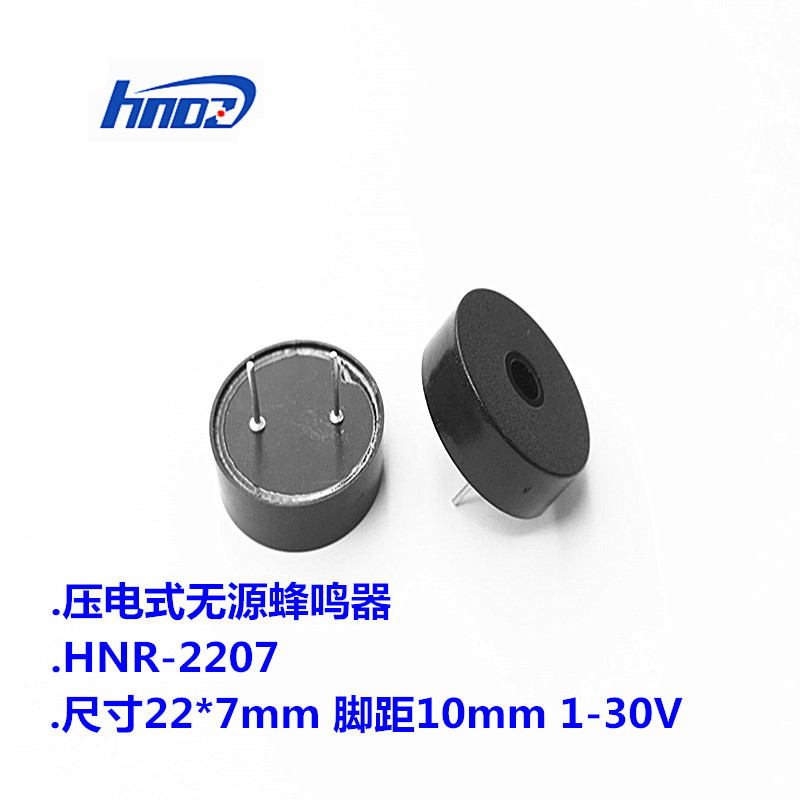

型号Part No:HNR-2207 | |||||

1 | 额定频率 Resonance Frequency (KHz) | 4.0 | |||

2 | 最大电压 Max Input Voltage (Vp-p) | 30 | |||

3 | 电容量 Capacitance at 1000Hz (nF) | 15±30% | |||

4 | *声压级Sound Output at 10cm (dB) | ≥90 at4.0KHz Square Wave 9Vp-p | |||

5 | *消耗电流 Current Consumption (mA) | ≤9 at4.0KHz Square Wave9Vp-p | |||

6 | 工作温度 Operating Temperature (℃) | -20~+70 | |||

7 | 储存温度 Storage Temperature (℃) | -30~+80 | |||

8 | 单品重量 Weight (g) | 2.3 | |||

9 | 外壳材料 Housing Material | 黑色Black PPO | |||

带*号指标需要在额定电压下测试 *Applying rated voltage | |||||

| |||||

蜂鸣器焊接方法 Buzzer Soldering process | Soldering Parameter | ||||

温度Temp.(℃) | 时间Time(Sec.) | 可焊接次数Times | |||

回流焊 Reflow soldering | 245±15 | 180℃预热 40~70秒 245℃ 3秒 above 180℃time40~70 | 3 | ||

★波峰焊 Wave soldering | 255±5 | 4~6 | 2~3 | ||

★手工焊 Manual soldering | 350±10 | 2~5 | 2~3 | ||

接插件 | |||||

带★号为推荐的焊接方法 Remark:★ Instance Soldering Process | |||||

| |||||

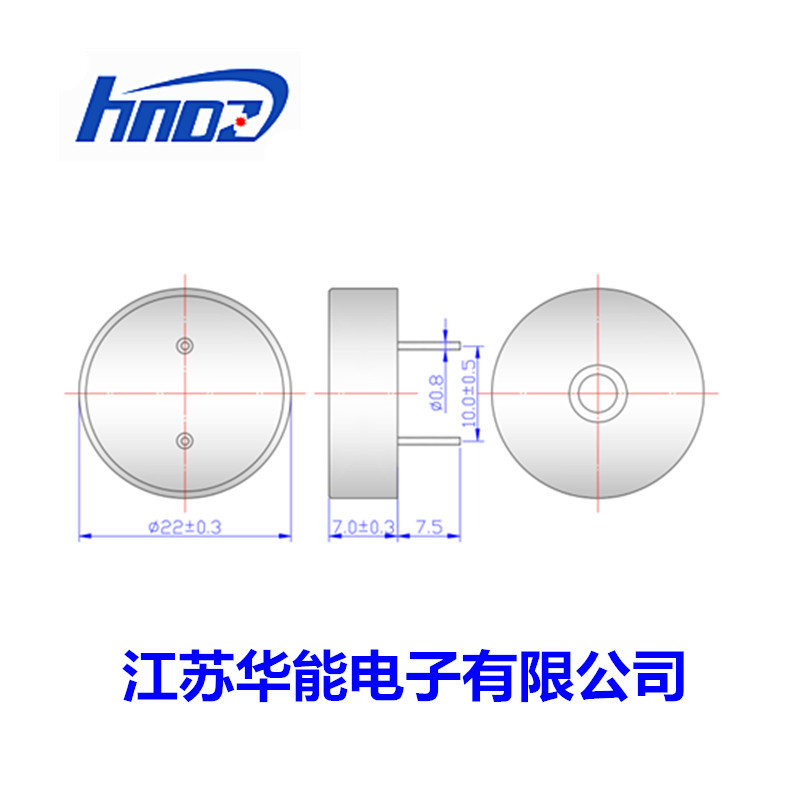

外形图DIMENSIONS(UNIT: mm) 未标注公差按±0.5mm计算 Tolerance:±0.5mm Except Specified | |||||

| |||||

测试方法 TEST METHOD | 频响曲线 FREQUENCY RESPONSE | ||||

|

| ||||

-2-

江苏华能电子有限公司 | ||

型号 Part No:HNR-2207 | ||

可靠性测试 RELIABLY TEST | ||

项目 ITEM | 测试条件 TESTING CONDITION | 试验后要求 VARIANCE AFTER TEST |

高温试验 High Temperature Test | 产品置于+80±2℃试验箱中,先工作2小时,然后在正常大气压条件下恢复2小时后,进行测量。 After being worked in a chamber at +80±2℃for 2h and then being placed in natural condition for 2h,sounder shall be measured. | 试验后,声响器的声级变化值在±10dB之内,外观无变化(例如:开裂,氧化,损伤,变形等现象) After test,the transducr S.P.L.difference shall be within±10dB,and the appearance not exist any change to be harmful to normal operation(e.g.cracks,rusts,damages and especially distortion)

|

低温试验 Low Temperature Test | 产品置于-30±2℃试验箱中,先工作2小时,再放置16小时,然后在正常大气压条件下恢复2小时后,进行测量。 First being worked in a chamber at -30±2℃for 2h and then being planed in a chamber at -30±2℃for16h,finally being placed in natural condition for2h,sounder shall be measured. | |

恒湿试验 Humidity Test | 产品置于湿度为90~95%R.H,温度为40±2℃试验箱中48小时,然后在正常大气压条件下恢复2小时后,进行测量。 After being placed in a chamber with 90 to 95%R.H.at+40±2℃for 48h and then being placed in natural condition for 2h,sounder shall be measured. | |

振动试验 Vibration Test | 振幅为0.75mm,频率为10~30~10Hz,三个不同轴方向各振动1小时,试验后测量。 Sounder shall be measured after being applied vibration of amplitude of 0.75mm with 10 to30 to10Hz band of vibration frequency to each of 3 perpendicular directions for 1hour. | |

自由落体试验 Freely Falling Test | 在0.8米高处,将产品三方向自由落体在木板上,试验后测量。 Sounder shall be measured after freely falling the products from 0.8m high to the wooden board with three sides per time. | |

碰撞试验 Collision Test | 加速度100±10m/s²,脉冲持续时间16ms,重复频率1~3次/min,次数1000±10次。试验后测量。 Sounder shall be measured after the test of acceleration 100±10m/s²,impulse lasting time 16ms,repeat frequency 1~3/min and time 1000±10. | |

可焊性试验 Solderability | 引线剥头/针脚浸入松香焊剂3秒,然后再浸入+250±5℃的锡锅中3±0.5秒,引线剥头表面应覆盖一层光滑明亮的焊料。 Lead terminals are immersed in rosin for 3 seconds and then immersed in solder bath at +250±5℃for 3±0.5 seconds,terminals should be covered with the clean solder. | |

引线/针脚强度试验 Terminal Strength Pulling | 引线/针脚应承受1N拉力,拉力时间10秒,引线无松动和脱落等现象。 The force 10 seconds of1N is applied to each terminal in axial direction.no looseness and falling off. | |

-3-